When people talk about 3D printer performance, they usually focus on:

- accelerations

- input shaping

- linear rails

- hotends

- multi-material systems

- slicer tuning

But the truth is simple:

None of that matters if your frame moves.

A printer can only be as accurate as the structure it’s built on.

This is especially true when you start pushing into high-end print speeds, IDEX systems, and dual-gantry motionlike we’re exploring with our Trident-based prototype.

So today, we’re looking at the one part of a CoreXY/IDEX frame that actually moves under load — the joints — and the stiffeners we designed to eliminate that weakness.

The Real Weak Point of a 2020 Frame Isn’t the Aluminum

The Voron Trident (and most CoreXY printers in the 200–350mm class) rely on 2020 aluminum extrusion.

2020 is:

- light

- stiff

- inexpensive

- easy to source

- ideal for hobby and prosumer printers

But the aluminum is not the problem.

The weak point is where the extrusions connect to each other:

- blind joints

- hidden T-nuts

- corner blocks

- friction-clamped fasteners

Under normal speeds, these joints are acceptable.

Under high acceleration, heavy toolheads, or dual-gantry loads, they flex.

And once the joints flex, the printer shows it:

- ringing

- inconsistent first layers

- inconsistent XY offsets

- extra work for input shaping

- motion artifacts that look like slicer errors

This is why stiffening the frame corners is one of the highest-value upgrades you can make when pushing a machine beyond factory capability.

Printed Stiffeners Work Because of Geometry — Not Because Plastic = Metal

We’re honest about material limitations:

- You can’t turn ASA into aluminum.

- You can’t make 2020 behave like 3030 purely through filament choice.

- You can’t “filament your way” to metal rigidity.

But you can change the structural behavior of the frame by reinforcing the joints, not the extrusions.

And this is where printed stiffeners are extremely effective.

The key insight:

Geometry gives you stiffness, not the filament.

A 10mm-thick, 60mm-tall triangulated bracket creates a load path that dramatically reduces flex, even if the material itself is nowhere near metal stiffness.

Even PLA stiffeners would help.

But for a serious machine — especially one with a heated chamber — ASA and ABS are the practical choice.

Why ASA and ABS (and Their GF/CF Variants) Are Perfect Here

We experimented with CF and GF filaments:

Carbon Fiber (CF built-in filament):

- Highest stiffness

- Most dimensionally stable

- Also the most brittle

Glass Fiber (GF filaments):

- Slightly lower stiffness

- Much tougher and less brittle

- Better for parts that take real-world vibration

Plain ASA / ABS:

- Good heat resistance

- Easy to print

- Plenty strong for structural brackets

- The difference between 2.8 GPa and 3.5 GPa stiffness is irrelevant once geometry is doing the work

We don’t need PEEK.

We don’t need Nylon.

We don’t need a $5,000 printer to print the stiffeners.

This upgrade is about smart design, not exotic filament.

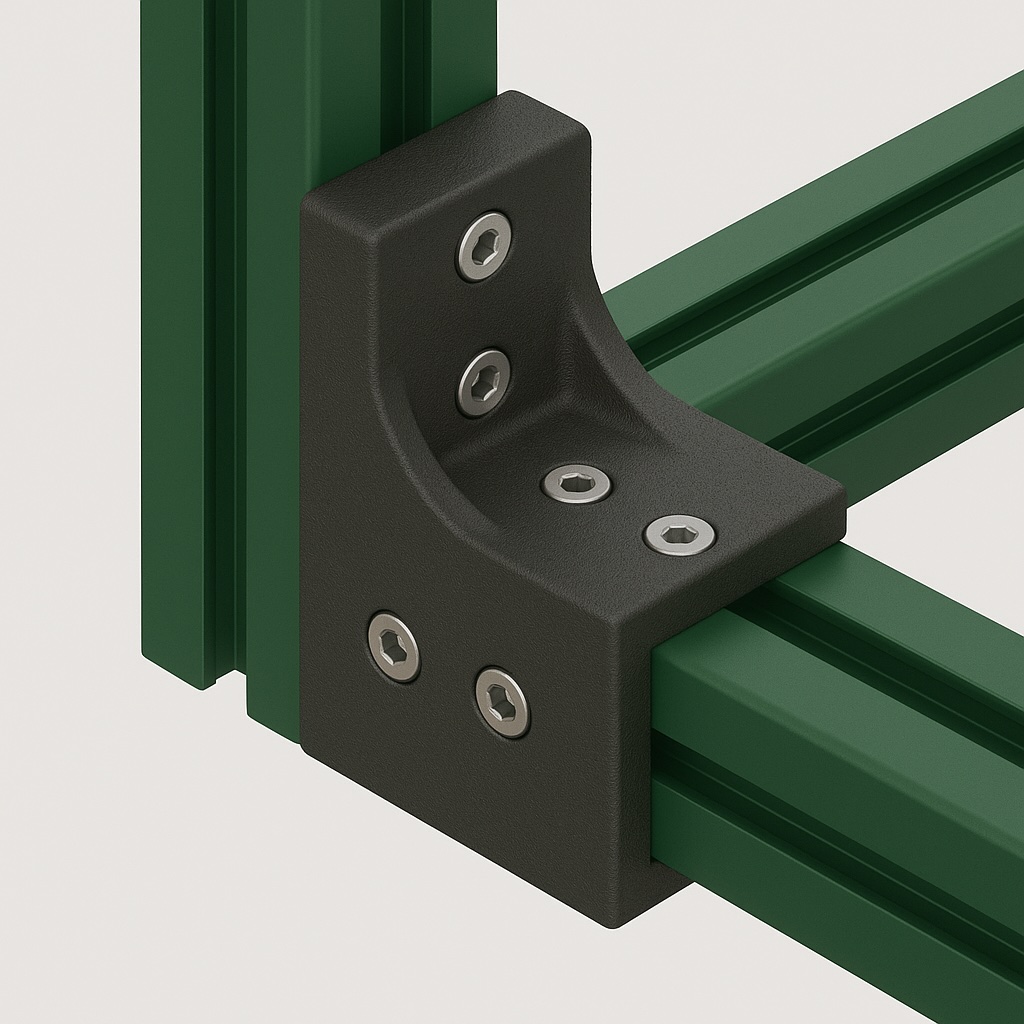

The Corner Stiffeners We Designed

We created structural gussets that match the Trident frame:

- 20×20mm footprint

- 10mm-thick bodies

- 60mm up each face of the corner

- Rounded triangular gusset for maximum rigidity

- Two M5 bolts per face

- Bolt-through into T-nuts

- 12 stiffeners across the upper frame

- Additional stiffeners planned for the electronics bay frame

Why this works:

- It eliminates flex at the blind joints

- It stabilizes the “motion zone” — the top ring

- It provides consistent behavior for dual-gantry testing

- It removes frame noise from resonance tuning

- It lets us focus on the actual motion system

This isn’t about making aluminum stronger — it’s about removing variables.

What a Stiffer Frame Means for a High-End 3D Printer

Once those joints stop moving, everything improves:

- consistent XY accuracy

- cleaner corners

- reduced ringing

- tighter IDEX toolhead offsets

- better input shaping

- fewer slicer “ghost artifacts”

- improved surface finish

- more reliable high-speed printing

A stiff frame is the foundation that all other performance sits on.

Without it, you’re tuning around a moving target.

With it, you’re tuning a machine that behaves predictably.

The Bottom Line

Upgrading to thicker extrusions is expensive.

Switching to metal corner plates helps, but still leaves gaps.

Rebuilding the entire frame is unnecessary.

So we solved the real problem:

Stiffen the joints.

Not the aluminum.

Not the gantry.

The joints.

With well-designed ASA/ABS (or GF/CF) stiffeners, a 2020-based printer behaves like a far more rigid machine — even under aggressive motion loads.

It’s a simple, functional, high-impact upgrade that transforms how a CoreXY or Trident-class printer performs.